Sustainability/ESG

Quality Management

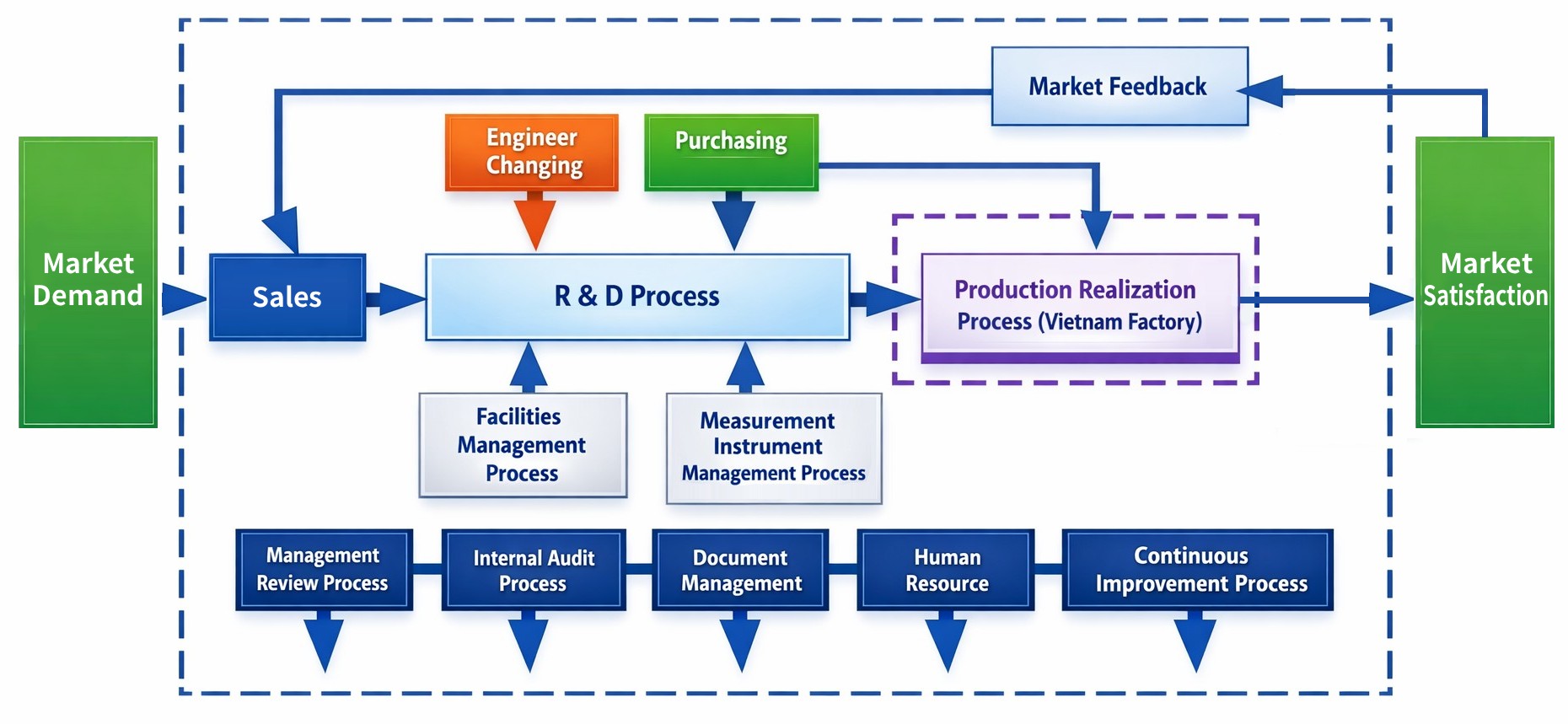

SonicFi collaborates with our manufacturing centers to shift the focus of quality management upstream to the Research & Development (R&D) and New Product Introduction (NPI) stages, strengthening design quality and enhancing process reliability.

- Risk Assessment Tools: During the NPI stage, we introduce rigorous risk assessment and verification using tools such as DFx (Design for Excellence) and FMEA (Failure Mode and Effects Analysis).

- Process Control: We develop precise Control Plans and error-proofing mechanisms (Poka-Yoke), combined with Lean Manufacturing principles to prevent errors and improve efficiency.

- Real-time Monitoring: The production line is equipped with automated ESD testing gates, facial recognition systems, and EPA (Electrostatic Protected Area) zones. All monitoring data is linked to a real-time database to ensure proper personnel protection and prevent product reliability issues caused by static electricity.

- Continuous Improvement: Through a rigorous quality system, we implement Six Sigma concepts for continuous improvement to enhance First Pass Yield (FPY) and overall Production Yield (PY).

This lean and controlled quality management model not only ensures the achievement of quality goals but also effectively reduces raw material scrap, lowering costs for customers and practicing resource sustainability.

| Category | Certification Standard |

|---|---|

| Quality | ISO 9001 Quality Management System |

| TL 9000 Quality Management System for Telecommunications | |

| Information Security | ISO 27001 Information Security Management System |

| Environment / Occupational Safety | ISO 14001 Environmental Management System |

| ISO 45001 Occupational Health and Safety Management System | |

| ANSI/ESD S20.20 Electrostatic Discharge Control Certification |

Information Security & Customer Privacy

SonicFi follows the ISO 27001 Information Security Management System standard, establishing rigorous security protocols to ensure the confidentiality, integrity, and availability of information assets. We strictly comply with regulations to comprehensively protect the rights of employees, clients, and partners. We not only implement information security within our own operations but also extend these standards to supply chain management; our Product Manufacturing Center has also obtained ISO 27001 third-party certification, creating a comprehensive information security defense.

Throughout the product design, development, and manufacturing processes, SonicFi regards customer privacy and information security as core product responsibilities, adopting the principles of “Privacy by Design” and “Security by Default“. By incorporating privacy and security considerations during the product function planning stage, we are committed to ensuring customer privacy protection while providing connection, management, and communication functions for our networking products.

SonicFi products are designed not to collect any Personally Identifiable Information (PII) that can directly identify a natural person. When providing functions such as network connection, device management, and traffic optimization, products process technical or de-identified data related to network transmission performance only within the necessary scope, and do not involve the inspection or analysis of communication content.

If networking products require login or management via an account mechanism, the design purpose is solely for device identification, system management, and security control. The product interface clearly discloses the account usage statement, enabling customers to understand the purpose of the account and their exercisable rights. Products also provide account management functions, allowing users to terminate relevant services based on their needs, ensuring customers have full autonomous control over their networking product usage status and account data.

Regarding product information security management, our networking products comply with the cybersecurity requirements of the EU Radio Equipment Directive (RED). We conduct systematic security risk assessments and security scans prior to product launch and whenever necessary to verify the absence of high-risk vulnerabilities.

Through product-level designs that do not collect PII, autonomous account control mechanisms, and regulation-oriented security risk management, SonicFi continuously strengthens product performance in privacy protection and information security, fulfilling our responsibilities for product safety and privacy

Product Information

SonicFi implements product information transparency and commits to complying with labeling regulations for network communication electronic products in all sales markets. We strictly maintain standards for complete product labeling, covering product names, manufacturer information, material composition, declarations of hazardous substances, telecommunication certification marks, safety warnings, and recycling guidelines. Meanwhile, through diverse channels such as product packaging and user manuals, we ensure consumers can conveniently access complete information and fully understand the product’s environmental and social impact.

SonicFi incorporates rigorous risk assessment and control standards starting from the product development and raw material selection stages. We ensure products fully comply with regulations such as EU RoHS, REACH SVHC (Substances of Very High Concern), the Battery Directive, the Packaging Directive, PFOS, as well as US TPCH, California Proposition 65, and French packaging regulations. We continuously monitor global regulatory changes and implement compliance requirements to safeguard consumer safety and health.

Green Products

SonicFi upholds the core philosophy of “Recyclable, Low Pollution, Energy Saving” by integrating environmental sustainability thinking into Product Life Cycle (PLC) management. From raw material procurement, manufacturing, and logistics distribution to end-use and recycling, we assess the environmental impact of every stage. We take concrete actions to reduce our environmental burden by improving energy efficiency and expanding the application of recycled materials.

Regarding carbon footprint management, our Product Manufacturing Center implements greenhouse gas inventories and possesses the capability for ISO 14067 Product Carbon Footprint inventory and verification, ensuring our ability to disclose product carbon emission data.

SonicFi strictly prohibits the use of conflict minerals and controls hazardous substances in accordance with global regulations. In design and manufacturing, we prioritize the use of laser engraving technology to replace traditional stickers. This not only resolves defects often caused by printing but also reduces material scrap and resource waste due to defect rates. Furthermore, product casings utilize powder coating technology with high recovery rates, and external power solutions are selected to meet high energy efficiency standards, comprehensively minimizing environmental impact from the manufacturing source to end-use.

| Stage | Focus | Action & Details |

|---|---|---|

| Raw Materials | Eco-friendly Material Selection | • Raw materials are 100% compliant with RoHS and REACH hazardous substance standards; strict prohibition of conflict minerals.

• Products comply with the WEEE Directive, enhancing reusability through the use of recyclable materials and parts. |

| Manufacturing | Production Efficiency Enhancement | • Laser engraving is used for markings instead of label stickers, reducing the demand for sticker raw materials .

• The Product Manufacturing Center utilizes automated processes and monitoring to improve efficiency and yield, reducing production energy consumption and raw material scrap. • Implementation of a smart energy control system to enhance energy utilization efficiency. |

| Sales & Distribution | Plastic Reduction & Eco-packaging | • Use of 100% recyclable packaging materials .

• Structural design of packaging cartons reduces packaging volume and minimizes the use of plastic buffers, achieving higher delivery efficiency and lower plastic usage. |

| Usage | Energy-saving & Durable Design | • Fanless design for products under 100W to reduce operational energy consumption .

• Introduction of Scheduling PoE smart power management functions . • Multi-functional Bracket design to support diverse environmental usage requirements. |

| Disposal | Design for Easy Recycling | • Product recycling guidelines are clearly labeled, making it easy for consumers to recycle at the end of the product life .

• Following WEEE guidelines, components can be disassembled to the smallest unit for waste recycling . • No special tools are required for product disassembly, facilitating the recycling process. |

Eco-Friendly Manufacturing

SonicFi strictly complies with environmental regulations at all operational sites and extends environmental management practices to our product manufacturing operations. Our Product Manufacturing Center has obtained third-party certification for the ISO 14001 Environmental Management System.

Regarding climate action and energy transition, we collaborate with our manufacturing centers to drive energy transformation, with plans to gradually introduce renewable energy. Simultaneously, we have implemented multiple energy-saving measures, including the comprehensive adoption of LED lighting, the introduction of smart energy management systems, the upgrade of air compressor efficiency and high-performance chillers, and the implementation of preventive equipment maintenance. These measures aim to significantly reduce energy loss by maintaining optimal operational efficiency.

- Waste Management: The Product Manufacturing Center follows ISO 14001 standards to supervise the waste disposal process. In addition to setting up compliant waste sorting and storage areas, all waste is entrusted to government-approved qualified vendors for removal. SonicFi conducts annual volume statistics and flow tracking. In 2024, waste disposal was 100% compliant with legal standards, achieving zero environmental hazard incidents.

- Water Resource Management: Although SonicFi’s manufacturing process does not involve water-intensive procedures, we manage water resources with high standards. We utilize the World Resources Institute (WRI) tools for assessment, confirming that neither our company nor our manufacturing centers are located in water stress hotspots. Regarding domestic wastewater generated at manufacturing sites, we mandate proper treatment in accordance with local regulations and commission third-party agencies annually to conduct water quality testing. This ensures discharge compliance and avoids negative environmental impacts. To further enhance water utilization, SonicFi works with manufacturing centers to introduce wastewater purification and reuse systems, utilizing treated wastewater for irrigation or toilet flushing to implement water resource recycling.

Human Rights Management

SonicFi strictly adheres to laws at all operational sites and follows international standards such as the Universal Declaration of Human Rights, the UN Global Compact, and the ILO Fundamental Conventions. We are committed to creating a diverse and inclusive workplace, strictly prohibiting forced labor and child labor, and eliminating all forms of discrimination.

This human rights policy applies not only to our company but also strictly requires compliance from our supply chain partners, ensuring that no individual is treated unequally based on gender, age, race, religion, or political stance.

We regularly conduct “Human Rights Due Diligence (HRDD)” on our product manufacturing centers and supply chain to proactively identify and prevent potential risks. The scope of the investigation covers basic labor rights, occupational health and safety, privacy protection, and the rights of vulnerable groups. Through continuous tracking and management, no major human rights violations occurred this year, demonstrating the effectiveness of our human rights risk management mechanism and our ongoing deepening of corporate social responsibility.

Occupational Health and Safety SonicFi aims for “Zero Harm, Zero Occupational Diseases, and Zero Accidents” by establishing a comprehensive occupational health and safety management system. In addition to implementing internal risk identification, our Product Manufacturing Center has obtained third-party certification for the ISO 45001 Occupational Health and Safety Management System. The management scope covers all employees and non-employee workers (such as contractors), ensuring that every worker in the supply chain operates in a safe and secure environment.